Textiles that satisfy international fire standards are an absolute must in the hotel sector thus putting a special challenge to hotel designers and interior decorators. They have to respect the fire regulations and at the same time create a stylish interior that has to fulfil design guidelines and distinctive individual requirements. Trevira CS fabrics meet the important fire safety standards that have been defined worldwide and stand out for their permanently flame retardant qualities.

It is the built-in safety which makes the difference. In contrast with other fibres and textiles which owe their flame retardant properties to a finish that must be replaced after washing or cleaning, Trevira CS provides permanent safety which cannot be reduced by use, cleaning or ageing. This is due to the chemical structure of the polyester fiber: the flame retardant properties are firmly anchored in the fiber and cannot be altered by external influences.

Trevira CS fabrics can come in 3 different versions. Trevira CS stands for fabrics made from 100 % virgin flame retardant Trevira® material.

Trevira CS flex marks fabrics with additional functions and design elements. These can be achieved by using special flame retardant yarns, lending them sound absorbing properties or melange effects, to name just two of the broad range of variations. The fabrics may contain up to 25 % of such non-Trevira® yarns.

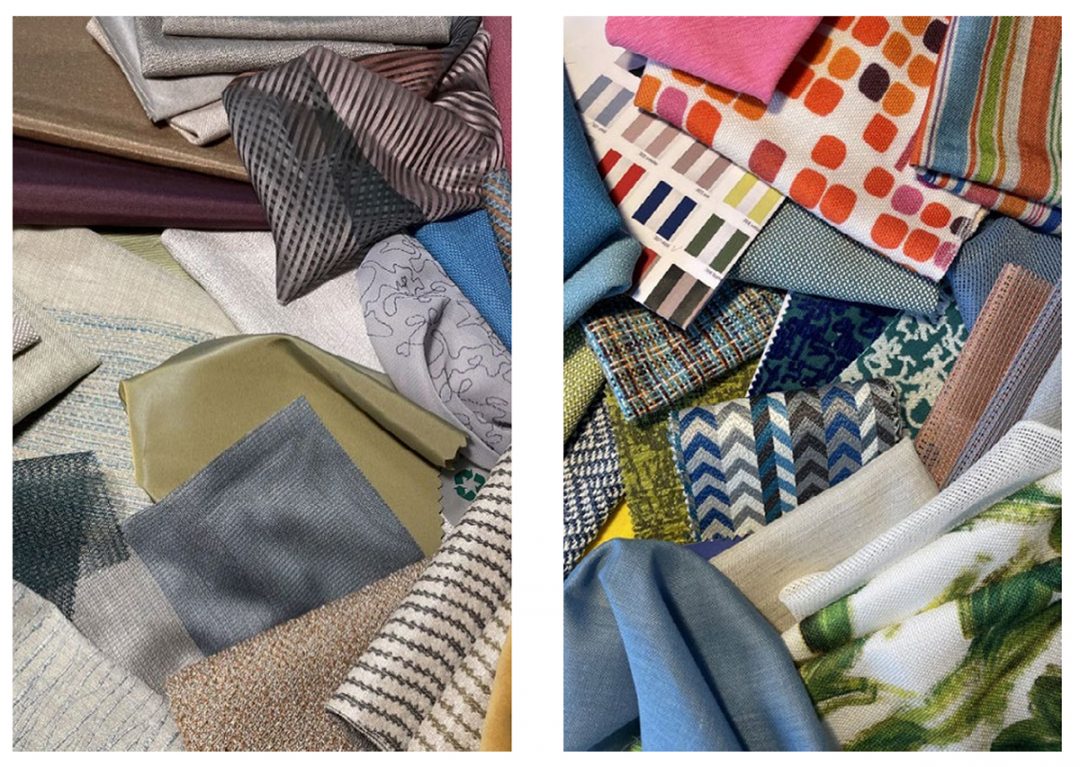

The Trevira CS eco brand stands for flame retardant textiles with at least 50% recycled material content obtained in either pre-consumer or post-consumer recycling processes. All flame retardant, recycled Trevira® products are GRS (Global Recycled Standard) certified. Due to their inherently flame retardant properties, Trevira CS fabrics create a safe, attractive and comfortable environment for hotels, restaurants, hospitals, offices, public buildings, railways, aircrafts and cruise ships. A wide range of Trevira CS collections with thousands of designs is available worldwide. The fabrics are used as curtains, drapes, decorative and upholstery fabrics, in interior sun protection and as wall coverings or room dividers. In all applications functionality and performance are a must. However, Trevira CS has a lot more to offer. From a sustainably furnished ambiance, to a luxurious interior or a casual outdoor area, to a cozy retreat – Trevira CS creates a high-end aesthetic, an atmosphere that inspires and appeals to our emotions – and does so with fabrics that are safe.

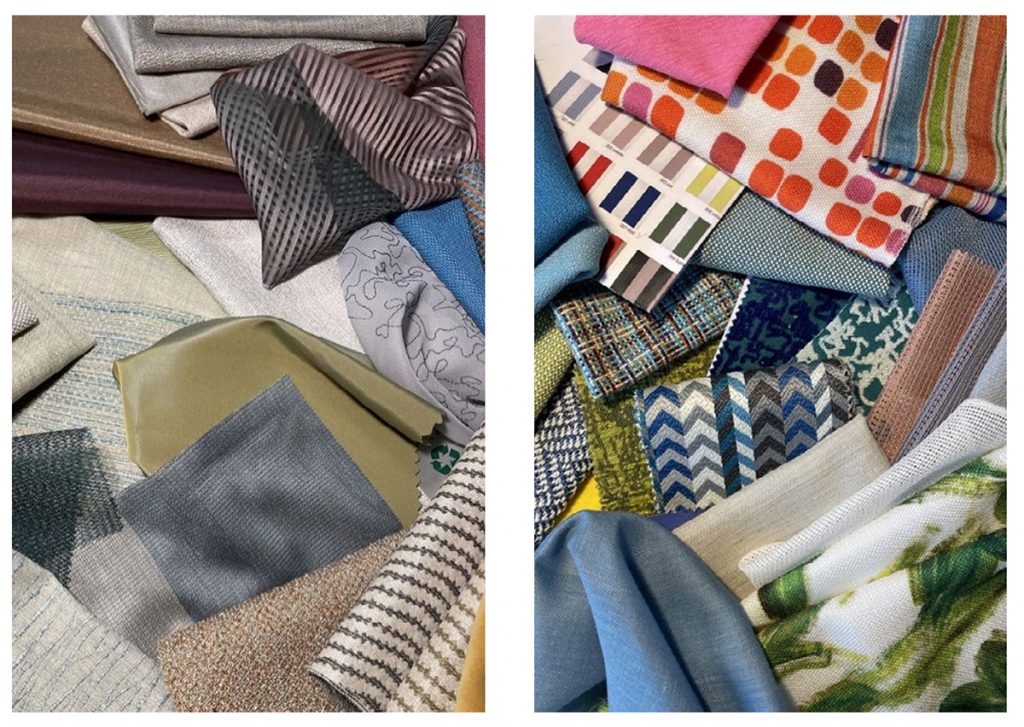

When safety meets color

A range of 30 flame-retardant, spun-dyed, UV-stable Trevira CS filament yarns is available for the textile design of outdoor areas. Spun-dyed yarns give textiles an enduring color quality and long-lasting durability. In addition, they are easy on the environment as dyeing processes for yarns and fabrics are no longer necessary, thus saving energy, water and chemicals. The yarns can also be used for making trimmings providing fresh yarns for an old craft.

When Safety meets Sustainability

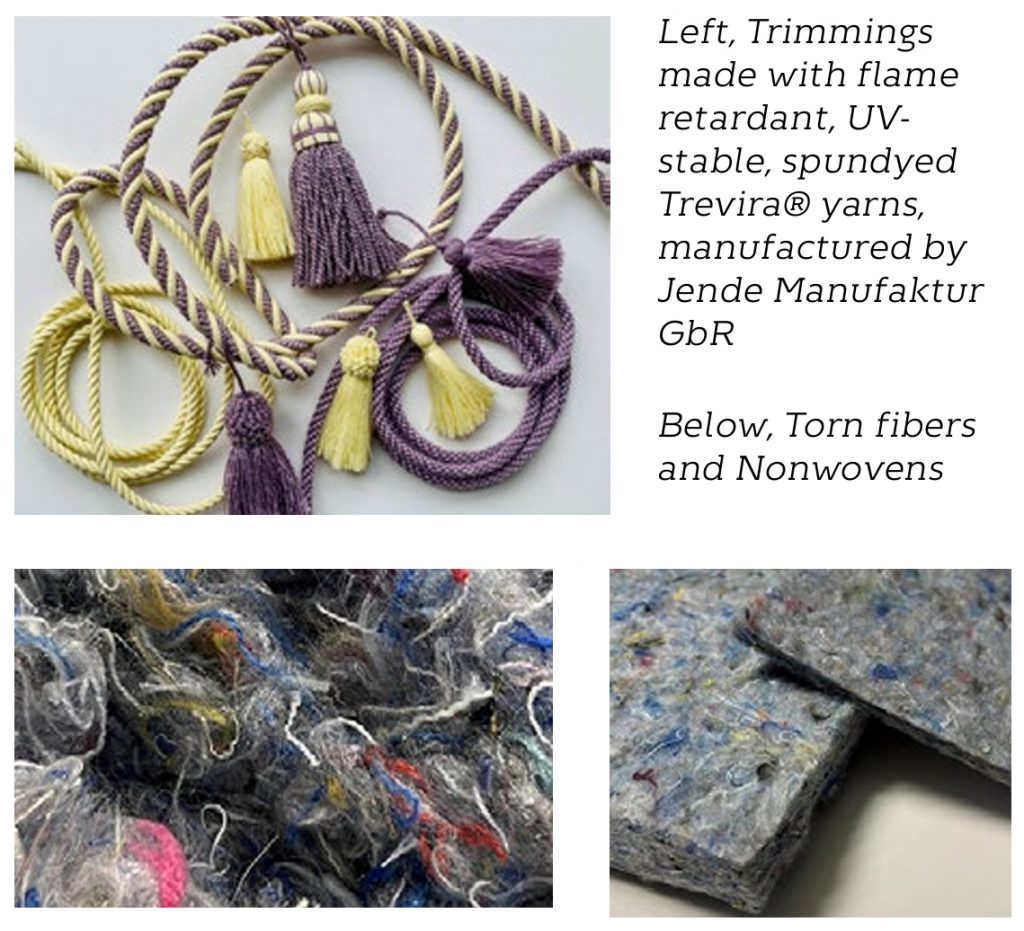

Trevira CS takes multiple approaches to enhance its sustainability performance. One approach is to take care of fabrics that are no longer needed. For some years already, Trevira CS has had a take-back program in place. Used Trevira CS fabrics (post-consumer) or unsold Trevira CS residual materials (pre-consumer) can be recycled as part of the Trevira CS return program. The returned fabrics are mechanically recycled and shredded into torn fibers, which are further processed into nonwovens with various specifications, if necessary, by adding new and/or low-melt fibers. These can be used in a variety of ways, like for thermal and acoustic insulation and as soundproofing panels. Nonwovens for acoustic panels are particularly interesting, becoming sound absorbing wall coverings, free-standing partitions, ceiling suspensions or decorative objects, to name a few.

The long-term goal in developing sustainable products is undoubtedly to enter a circular economy. For this new path, an innovative Trevira CS product development was launched, producing flame retardant fibers and filament yarns from chemically recycled raw material. By recycling valuable materials such as packaging material, waste can be avoided. The raw material obtained from this recycling process is comparable to the original material and can be used again in high-quality products. The greatest advantage, however, lies in the potential that this approach opens up for the future. If we use raw materials obtained by chemical recycling of PET packaging / bottles today, we could potentially recycle textile waste in a similar fashion in the future. www.treviracs.com